Thursday, June 12, 2014

Wednesday, June 4, 2014

Sunday, June 1, 2014

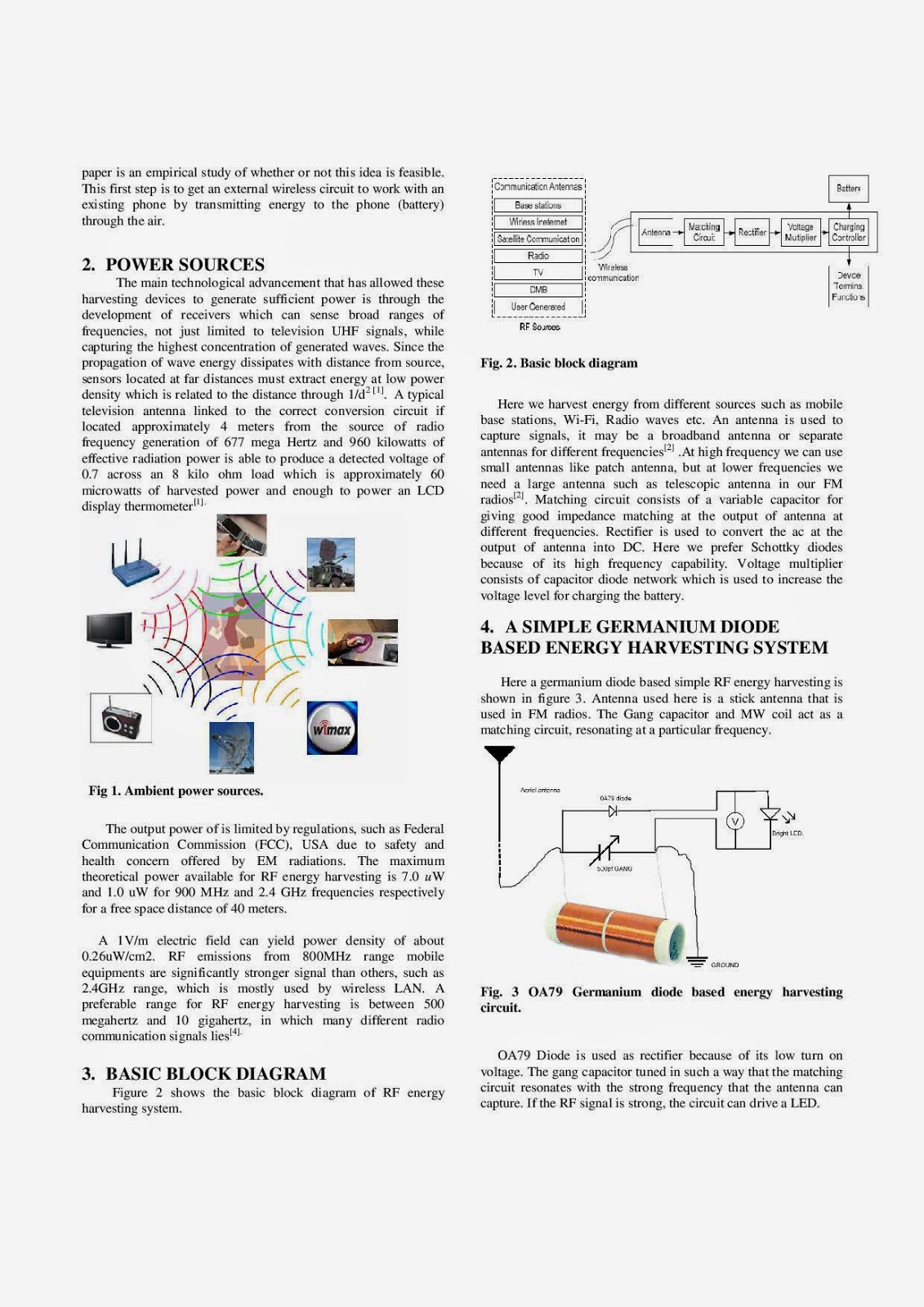

GM Piston Slap

Pistons rock as they cross TDC where the thrust load from the rod angularity shifts from one side to the other. This makes noise. Harmless..but it is the source of piston slap in most all situations.

To prevent this, pistons are designed with long, tapered, flexible skirts so that they can be fitted very tight in the bores when the bore and piston is cold. The taper of the skirt and flexibility of the skirt then prevents scuffing when the piston is hot. Also, the piston pin in OEM production pistons is always offset to one side....it is NOT in the middle of the piston. By offsetting the pin in the piston, artificial thrust load is created to control the piston "rocking" as it crosses over TDC.

Unfortunately, all of the above control techniques, common in past model engines to the extreme, create excess piston mass, cause friction and cost power and fuel economy. With the desire to build in as much power and free-revving capability and to improve fuel economy as much as possible thru friction reduction these design features are pushed in the other direction on modern engines.

Piston pin offset has been reduced over the years to a bare minimum today to reduce the thrust load generated and reduce friction. Pistons have been lightened up considerably by shortening the skirts. This creates less rotating/reciprocating mass which is good for power, free revving capability and fuel economy. Light weight pistons are great but the skirts, by necessity, are short making it hard to make them both strong and flexible and the shorter ckirts make them more prone to rocking.

Unfortunately, when the performance and fuel economy oriented pistons are run cold they are very prone to "slap" until they warm up to operating temperature.

The piston designers and development engineers are always treading the fine line between piston slap cold and friction and power/fuel economy loss when the engine is warm.

It is possible that you are hearing piston noise from an engine that is on the "high limit" for piston clearance so that it makes some noise cold. The good news is that the condition is harmless and that engine is probably a little more powerful (due to less friction) than a "quiet" counterpart. The bad news is that...it makes noise cold.

As an example of what the piston pin offset can do, it was common back in the early 70's to turn the pistons around "backwards" in the large displacement Chrysler engines to gain power. Those engines had large piston pin offsets to create thrust load to control the piston slap. So much thrust load and friction was created that just turning the pistons around in the bores was often good for 10 HP. The engines were very quiet with the pistons in correctly and they slapped like crazy, especially when cold, with the pistons reversed so as to reverse the pin offset.

Racing engines do not have the pin offset and thus the pistons slap like mad...but no one hears them over the open headers....

Positive Crankcase Ventilation (PCV) system

An internal combustion engine is built around a series of hollow cylinders, in each of which is a moveable piston designed to glide up and down inside it. A mixture of air and gasoline is pumped through a system of tubes called the intake manifold through each cylinder's intake valve (or valves), where a spark from a spark plug causes the mixture to explode in the open space at the top of the cylinder called the combustion chamber. The pressure from this explosion drives the piston in the cylinder downward, where it causes the crankshaft to rotate. The rotation of the crankshaft not only pushes the piston back up into the cylinder so it can do all this again, but it also turns the gears within the car's transmission that eventually make the car move. Meanwhile, the rising piston pushes the air and gas left over from the explosion back out of the cylinder through an exhaust valve.

However -- and this is where crankcase ventilation comes in -- a certain amount of that mixture of air and gasoline is pulled down by the piston and slips through the piston rings into the crankcase, which is the protective cover that insulates the crankshaft. This escaping gas is called blow-by and it's unavoidable. It's also undesirable because the unburned gasoline in it can gunk up the system and produce problems in the crankcase. Until the early 1960s, these blow-by gases were removed simply by letting air circulate freely through the crankcase, wafting away the gases and venting them as emissions. Then, in the early 1960s, positive crankshaft ventilation (PCV) was invented. This is now considered the beginning of automobile emission control.

Positive crankcase ventilation involves recycling these gases through a valve (called, appropriately, the PCV valve) to the intake manifold, where they're pumped back into the cylinders for another shot at combustion. It isn't always desirable to have these gases in the cylinders because they tend to be mostly air and can make the gas-air mixture in the cylinders a little too lean -- that is, too low on gasoline -- for effective combustion. So the blow-by gases should only be recycled when the car is traveling at slow speeds or idling. Fortunately, when the engine is idling the air pressure in the intake manifold is lower than the air pressure in the crankcase, and it's this lower pressure (which sometimes approaches pure vacuum) that sucks the blow-by gases through the PCV valve and back into the intake. When the engine speeds up, the air pressure in the intake manifold increases and the suction slows down, reducing the amount of blow-by gas recycled to the cylinders. This is good, because the blow-by gases aren't needed when the engine speeds up. In fact, when the car is up to speed, the pressure in the intake manifold can actually become higher than the pressure in the crankcase, potentially forcing the blow-by gases back into the crankcase. Since the whole point of positive crankcase ventilation is to keep these gases out of the crankcase, the PCV valve is designed to close off when this happens and block the backflow of gases.

Remapped engines - ECU remaps

Back in the good old days, the task of timing the ignition spark was performed by the distributor. The greater the RPM, the more the timing would advance. It was clunky and mechanical but seemed to work quote well. This did a reasonable job, but for the most effective power you would need to vary the timing to a greater degree than a fixed ratio advance curve. The electronic ignition system was born giving much finer control over fuel delivery and spark timing. A complete map of variables was entered into the ignition program and preset timing would be read from a table.

Now air temperature, engine speed, engine load and even control over turbo/wastegate control & fuel delivery rates means that precise management of the engine ignition timing is possible and you can achieve the maximum power output throughout the rev range.

So what does ECU remapping do?

Electronic ignition allows the manufacturer to fine tune economy at popular road speeds such as 30mph, 56mph and 70mph where most cars spend a large proportion of their time. It is now possible to advance the timing if the throttle is wide open to give greater power or back off the timing when cruising at constant speed. When a manufacturer creates a timing map they build into it a big margin of error to cope with: adverse temperature ranges, minor faults & bad conditions. Manufacturers do not want people breaking down, suffering premature parts failure or to get a reputation for uneconomical cars so they build in a wide margin of tolerance. Different countries use different grades of fuel and have varying degrees of extreme weather conditions, all these factors add to the fudge that has to be done to keep all the cars working well across the globe. Each car that leaves the production line is also unique, some achieve 10bhp less and others can be 10bhp up on standard specs, depending on how well the components are machined and put together. So rather than put each car through a unique assessment and get a bespoke timing map, they adopt a standard one map fits all philosophy.It is also a fact that manufacturers use the remap to produce different power versions of the same engine and get lower insurance cover ratings and better fuel consumption. You start to see the fantastic scope for improvement, when you add into the mix the fact that the average TorqueCars reader will be adding better performing components to the car, you have a really strong case for a remap. Other things that the manufacturer builds in to their map equation is the possibility of user neglect i.e. infrequent servicing with items struggling like dirty plugs, bad leads, clogged air filter, partially

blocked injectors etc... The list goes on.

Anyone who has added performance parts to their engine should consider a remap. If your car is a turbo model & has electronically controlled fuel injection, there are massive power gains on offer and TorqueCars would strongly recommend a remap. What are the hidden costs or drawbacks? You will need to be prepared to keep the car serviced more frequently, and, sometimes decreasing the service interval by half. When you fill up you are also restricting yourself to high quality fuel and you must be prepared to replace components that fail due to the extra work they are doing. When an engine is tuned to produce more power, you are also creating more stress and strain, so things will start to fail such as air flow sensors. Also turbos can wear out, other major components like pistons and bearings will need care and attention and you will find that the clutch lasts a shorter time. If you do not have a turbo there's very little to be gained by a remap alone - perhaps only a few BHP so TorqueCars' recommendation for non turbo cars is to modify everything else first (cams, pistons, increase compression, engine balance, air intake, exhaust, head work, bigger valves etc...) after these things have been done you can then consider a remap which will help you get the full benefit from them.

On the subject of turbos, (briefly though as we have a comprehensive article on turbos in the forced induction section), a remap will often introduce boost from lower down the rev range and because of this the turbo is running faster and hotter. In this situation you must let the turbo cool down a little before shutting off the engine, otherwise the oil will degrade and you will have an expensive turbo. repair on your hands. Fitting a turbo timer will also help with this problem and keeps the engine ticking over. Of course the amount of power you choose has a bearing on the reliability and cost of running the car. Many people go for an off the shelf remap which are on offer all over the country and typically cost around £200-£500. This is better than the manufacturers map in that it uses tighter parameters but it is still a one size fits all job. If you are after big power gains and have changed major components like the turbo, waste gate and have done extensive engine work then a custom remap is the best option.

Switchable remaps.

Things have moved on and it is now possible to have a few maps stored which you can select from. It is typical to have a valet mode to stop the boy racers at the garage thrashing your pride and joy on the "test run" to bed in the new wiper blades they have fitted. Then there is often an economy option to give very frugal fuel consumption, particularly useful when cruising on long journeys. Then you have the 'sport' or 'power' modes which give lots of power and often require high octane fuel. TorqueCars strongly recommend that you get a switchable remap - it may cost a little more at the outset but you will avoid many of the pitfalls of running a high power remap all of the time by doing this and get the best of both worlds. Please do not confuse a remap with the little "tuning boxes" you can buy for £50 which generally obtain little more than a £3 resistor and often do little more than fool the car into thinking the air is cooler than it is. If it was really this easy to get more power from a car then the manufacturers would have already done that themselves. Some cars are not easy to remap, I remember that the Rover MEMS & Toyota ECU's are a case in point. The Manufacturer holds the key to the ECU and locks their Map into their firmware. Some ECU's are simply not reprogrammable. So what can you do? Is there an option? Well thankfully there is and they are called piggy back ECU's or aftermarket ECU's. Piggy back & Aftermarket ECUs: Piggy back ECUs connect between your existing ECU and the engine sensor inputs and outputs. All work slightly differently and apply some or all of the following combinations.

Some will adjust the sensor readings such as air temp, engine speed, crank position and effectively lie to the standard ECU forcing a more aggressive timing. Some will actually perform their own calculations and take over control of some aspects of engine management like turbo waste gate control and ignition timing. Some will take the standard ECU output and modify the signals sent to change timing and learn to guess the next output a split second before it is needed using the base ECU map and just enhancing it a little. Tuning boxes are relatively new and these alter readings going to and from the ECU giving extra power or economy. Aftermarket ECUs are often direct replacements for the car's ECU and will take over all the functions associated with it. They are generally faster and able to cope with a wide variety of additional factors such as water/methanol injection and a turbo timer. Be wary though, as some piggy back ECUs and aftermarket ECUs do not include knock protection. If this is the case then set your timing conservatively and use high octane fuel. As with all ECU upgrades you are still dependant on having the car in top condition as you are removing the tolerances built in for dirty plugs, cheap fuel, or minor electrical faults.

Diagnose Engine Surges, Stalls, Misfires, Power Loss

Mass Air Flow Sensor failure symptoms

- Low gas mileage, shuddering, stalling, knocking or pinging.

- Check engine light may illuminate on the instrument panel.

- Engine may start normally in some cases, but will cut off after a few minutes (or seconds) of operation.

- Engine may be unable to start at all.

- No spark from the spark plugs.

- Engine may experience backfiring or irregular rpm function, if the vehicle starts at all.

- Long cranking time when starting cold

- Engine may run rough on an intermittent basis, poor idle, poor acceleration, stumbling and/or hesitation.

- Drop in mileage and stalling upon acceleration.

- Engine may start normally in some cases, but will cut off after a few minutes (or seconds) of operation.

- Engine may be unable to start at all.

- No spark from the spark plugs.

- Engine may experience backfiring or irregular rpm function, if the vehicle starts at all.

- Long cranking time when starting cold

- Engine may run rough on an intermittent basis, poor idle, poor acceleration, stumbling and/or hesitation.

- Drop in mileage and stalling upon acceleration.

- A car that seems to hesitate or stumble during acceleration may have a faulty throttle position sensor.

- If your car idles unevenly or hesitates intermittently, regardless of acceleration, the throttle position sensor may simply have a loose connection.

- A sudden decrease in gas mileage.

- Check engine light may illuminate.

- Smog test failures can also be an indication of a failed oxygen sensor. EPA and CARB say 50 to 60% of all smog and emission tests related failures are attributed to the defective oxygen sensor. Faulty O2 sensor leads to either low or high CO emissions in the smog tests.

- Engine may idle roughly, hesitate, or stumble. A bad oxygen sensor causes an engine's air/fuel mixture to become too lean. Normally, an air/fuel mixture that is too lean (too much air, not enough fuel) will cause an engine to miss, or misfire, especially when an engine is idling.

- Check engine light may flash on your vehicle's dashboard.

- If the knock sensor is not working properly, you will likely hear sounds emitting from the engine.

- The vehicle will often shake or vibrate and misfire when the engine is started.

- Stronger than normal exhaust and burning smells due to the detonation in the cylinders.

- Fuel economy is often affected, causing the vehicle to burn more gas than usual and requiring frequent fuel replenishment.

- May have acceleration problems, such as dragging, hesitation or jerking from the engine during speed increases.

- A lack of spark because the spark plugs are not receiving the proper information to fire correctly.

- The fuel injectors may fail to operate.

- Rough idle may occur.

- May cause engine stalling and an inability to accelerate smoothly.

- Rough engine idle and/or misfire.

- Engine hesitation, which is normally most apparent during acceleration.

- Engine power loss and/or surging.

- The dashboard lights will go off when the car stalls and the speedometer and tachometer (if you have one) will go off and come back on again.

- Vehicle fails to start and stalls randomly while driving.

- Switch gets overly hot.

- A faulty IAC will cause stalling problems at idle.

- Most of the time if you hold the gas pedal down it will run fine. These symptoms can also come from an EGR valve that is stuck open.

- If you have a fast idle, check for an intake leak.

- Engine misfires causing the car to jump/buck occasionally while going along the highway. The fuel pump may act up for a mile or so two or three times and then run fine for the next 50 or more miles.

- As you accelerate, the car starts to go and suddenly seems like it is going to die. Immediately, it seems to restart and off you go.

- Power loss at highway speeds.

- Will turn over, but will not start.

- No spark from the spark plugs.

- Higher than normal amount of exhaust.

- Difficult to start.

- Engine may misfire, shake, hesitate, or stall if the timing is off.

- Distributor rotor will not rotate.

- Cylinder misfiring, engine shaking.

- Trouble starting on a regular basis.

- Starts okay but stalls and backfires once on the road.

- High-pitched squealing noise.

- A check engine light may be present.

- If the distributor failed the vehicle will crank but not start.

- A drop in power.

- A total coil failure will cause a no spark, no run condition.

- Decline in normal gas mileage.

- May have black smoke out of the exhaust and smell of gasoline, rather than smelling like normal exhaust fumes.

- May experience serious backfires, misfiring, and stalling.

- Typically harder to start, especially when cold.

- High RPM misfire.

- The car will start and run fine, but will stop running anywhere from seconds to minutes later. The engine may not restart immediately but if left to cool for about 10 minutes will start fine.

- Hesitation/misfire under acceleration.

- Failure to start.

- One or more of the spark plugs may have become fouled out and blackened.

- When you are idling the engine it is not running smoothly and it is sputtering and spitting like it is going to die. If you haven't changed your fuel filter in a while, you should do that first and see if it helps. If not, then check the fuel pressure regulator.

- Trouble starting the car. It will turn over but takes a few extra tries before it actually starts.

- Tail pipe may have black smoke coming out of it.

- Check the oil dipstick and see if you smell fuel on it.

- Gasoline may be dripping out of the tailpipe.

- The engine stalls when you press down on the gas pedal.

- Engine may hesitate, stumble, or stall.

- Rough engine idle.

- Decrease in engine power.

- You might notice a leak from it, or a low oil pressure reading on the gauge.

- The car will die out at times.

- The most common sign of a bad speed sensor is a speedometer or odometer that stops working. Also, you may not be able to set your vehicle to cruise control.

- The following codes may be set: GM 24, Ford 27, 29, 452, Chrysler 28, 15

- Typical OBD-II codes for a malfunctioning VSS are: P0500, P0501, P0502, P0503, P0716, P0718

- May send out a wrong "too fast" signal, shutting down fuel flow at the wrong time.

- Random or intermittent sudden loss of power and poor performance, only to have the engine resume normal operation.

- Hesitation, roughness or sporadic jumps in your vehicle's transmission when you try to shift gears.

- May rumble or idle irregularly when you start it, may burn more fuel than normal, may lose power suddenly due to wrong signals sent from the speed sensor to the fuel system.

- Loss of anti-lock brakes, ABS warning lamps on the dash may be lit.

- RPM limiter may be decreased.

- Engine will rev or surge suddenly, possibly causing the engine to sputter and die. May also surge while idling, such as at a stop light. You may also notice the engine idles rough when the car is on but not driving down the road.

- The spark plugs may become fouled or coated with a white powdery substance.

- Loss in engine power. Decreased fuel efficiency, consuming more gas than normal.

- Check Engine Light may illuminate.

- A rich or lean fuel mixture. May notice a gas smell even after warm-up and/or pinging at random times or all the time or whenever.

- Rough idle and Hesitation.

Friday, April 11, 2014

TORQUE & HORSEPOWER

One of the most confusing (and frequently contentious) questions in the automotive realm is the difference between horsepower and torque. You may have heard any number of pithy expressions, like “horsepower sells cars, but torque wins races,” or fans of big-engine muscle cars complaining that 200-horsepower four-cylinder engines are “gutless.” Surprisingly few of the worthies who throw around comments like that, though, are actually able to define the difference. What IS the difference between horsepower and torque, and what effect do they have on how a car performs?

UNDERSTANDING TORQUE

If you stayed awake through high school physics, you may dimly recall that torque istwisting force — that is, a force that tries to cause an object to rotate around a particular axis. For example, if you turn a doorknob or spin a roulette wheel, you are applying torque to it.

If we were in physics class, we’d say that torque is the cross product of the vector of the force applied and the distance vector. The force vector is the direction in which you’re applying force. The distance vector is (at its simplest) the distance between the point where you’re applying the force and the axis of rotation. For example, imagine you are using a wrench to turn a bolt. In that case, the center of the bolt is the axis of rotation. If the wrench is one foot long and you apply ten pounds of force to the end of it, you are applying 10 pounds-feet of torque to the bolt. If the wrench was two feet long and you applied ten pounds of force at its end, you’d be applying 20 pounds-feet of torque.

What is engine torque? As you probably know, an internal combustion engine works by burning air and fuel. The energy of that combustion moves one or more pistons (or rotors), which act on the engine’s crankshaft, causing it to rotate. In a car, the rotation of the crankshaft turns the gears in the transmission, which turn the wheels. An engine’s torque is the amount of twisting force the pistons (or rotors) can exert on the crankshaft.

UNDERSTANDING HORSEPOWER

Now, what is horsepower? Again recalling that long-ago physics class, power is workperformed over time. Mechanical work represents force exerted over distance — for example, moving a 10-pound weight a distance of one foot represents 10 foot-pounds of work. Power is the rate at which that work is performed. One mechanical horsepowerrepresents the ability to do 550 foot-pounds of work per second, or 33,000 foot-pounds of work per minute. (One metric horsepower represents a rate of 75 kilogram-meters per second; a metric horsepower is about 735 watts, whereas a mechanical horsepower is equivalent to about 746 watts.)

The brighter students among us may have noticed the similarity between the units for work — foot-pounds (ft-lb) — and the units for torque — pounds-feet (lb-ft). In fact, the units are the same; the only reason they’re written differently is to avoid confusion. For an engine with a rotating crankshaft, then, one horsepower is equivalent to exerting 550 pounds-feet of torque per second.

Remember that torque is a twisting force; that means that if applying torque to an object will tend to cause the object to rotate, rather than move in a straight line. Therefore, if torque produces any work, we have to measure how much rotation it imparts (angular speed), rather than how far it cause the object to move. Angular speed is usually expressed in terms of radians per second or radians per minute (one radian is 180 degrees divided by π, or about 57.3 degrees), but since we usually measure engine speed in terms of revolutions per minute (rpm), it’s more useful to think of it that way. One revolution is 360 degrees, which is equal to 2π radians. If 1 horsepower equals 33,000 lb-ft of work per minute, then we can calculate an engine’s power based on its torque (in lb-ft) and its engine speed (in rpm):

Power (hp) = Torque (lb-ft) x 2π x Rotational Speed (rpm) / 33,000orPower (hp) = Torque (lb-ft) x Rotational Speed / 5,252.113

For example, if an engine produces 200 lb-ft of torque at 4,000 rpm, it has 152.3 horsepower (200 x 4,000 / 5,252.113) at that speed.

The upshot: Horsepower depends on torque and engine speed. If your engine produces more torque, it also makes more power; if you run the engine at a higher speed, it also makes more power. It is entirely possible for engine A to make more power than engine B, even if engine B makes more torque — engine A must simply rev higher to make up for its torque deficiency.

TORQUE AND POWER CURVES

Engines used for stationary applications (generators, for example) or in aircraft spend most of their lives running at a constant engine speed. As a result, they produce their full, rated horsepower most of the time. Engines used in cars, trucks, or motorcycles operate over a broad range of engine speeds, from a few hundred rpm at idle to 10,000 rpm or more at redline. Since horsepower depends in part on engine speed, the amount of power the engine produces varies quite a bit at different points in its rev range. Engineers describe the relationship between an engine’s power and rpm as the power curve.

If an engine produced its maximum torque at all engine speeds, the power curve would be a straight line: that is, increasing rpm by 50% would also increase horsepower by 50% (as long as it didn’t rev the engine beyond its redline, which risks serious mechanical failure). That is true of electric motors, but it isn’t true of internal combustion engines. We will discuss the reasons for this in more detail in a future article, but for now, we’ll just say that an engine’s torque output also varies with engine speed.

All internal combustion engines produce their maximum torque at one particular engine speed; this is called the torque peak. Above or below the torque peak, the engine produces somewhat less torque than that maximum value. Just as an engine has a power curve describing how much power the engine produces at different points in its rev range, the engine also has a torque curve, describing how much torque it generates at different speeds. The engine’s design determines at what speed the engine’s torque peak occurs, as well as the shape of the torque curve. If an engine produces a fairly constant level of torque throughout its rev range, its torque curve is said to be flat. Electric motors, which usually produce close to their full torque output from zero rpm all the way to their maximum safe operating speed, have extremely flat torque curves. (Contrary to popular belief, the shape of the torque curve is not directly related to how much torque the engine produces. Two engines can have very similarly shaped torque curves, even if one has far more maximum torque than the other does. Again, we will look more at the factors that determine the shape of the torque curve in a future installment.)

An engine can be tuned to produce its maximum torque at the low end of its rev range, in the mid-range, or at high rpm. Modern engine designers have various tricks available to “flatten” the torque curve of an engine (that is, to keep engine torque close to its maximum through a broad range of engine speeds), but any given engine will be notably stronger in one range than in others.

Since power is a function of torque and rpm, the shape of the torque curve also determines the shape of the power curve. The horsepower curve will always peak later than the torque curve, but if the engine’s torque curve is strongest at low rpm, the power peak will also be relatively low. If the torque peak is at high rpm, horsepower will also peak at lofty engine speeds.

If you’ve ever driven a car with a tachometer, you’ve probably noticed that the engine spends much of its time at speeds well under 4,000 rpm. Since the horsepower peak of almost every modern engine is higher than 4,000 rpm, that means the engine rarely has a chance to develop its rated maximum power. Therefore, in normal driving, the shape of the torque curve is often more important than maximum power.

THE REAL WORLD (SORT OF)

To see how this works in practice, let’s consider a couple of real engines: Ford’s 4.0 L “Cologne” V6 (which powered the Ford Ranger and Explorer for many years) and Volkswagen’s turbocharged, four-cylinder 1.8T engine (used in several different configurations in a wide range of Volkswagen and Audi models).

The Ford Cologne V6 was an engine of venerable design dating back to the early 1960s. The 4.0 L (245 cu. in.) version was intended for truck use, so it was tuned for strong low-end torque. Its peak torque was 220 lb-ft at only 2,400 rpm; maximum horsepower was 160 at a modest 4,200 rpm.

Volkswagen’s 1.8T was a more modern and far more technically sophisticated engine with dual overhead camshafts, five valves per cylinder, and an intercooled turbocharger.Turbocharged engines tend to be “peaky,” putting out more power at high rpm, but Volkswagen designed it to have as flat a torque curve as possible. In fact, Volkswagen claimed that the engine produced its full maximum torque from 1,950 rpm to 5,000 rpm. VW offered it in several states of tune, but the one we’ll use for our discussion is the version found in later Mk 4 Golfs, Jetta/Bora sedans, and the SEAT León, which had 180 horsepower @ 5,500 rpm and 173 lb-ft of torque.

The best way to judge an engine’s torque curve is to hook it up to a dynamometer and see exactly how much torque it actually puts out at various rpm. We aren’t in a position to do that, but we can make some educated guesses about the torque curves for both engines based on their rated torque and horsepower peaks.

As we mentioned above, the Ford engine’s rated torque peak is at 2,400 rpm. Using the equation we derived earlier, we can calculate its power output at that speed: 101 horsepower (220 lb-ft x 2,400 rpm / 5,252). The V6′s horsepower peak comes at 4,200 rpm. Using the same equation, we calculate that it has 200 lb-ft of torque at that speed (160 hp x 5,252 / 4,200 rpm). We can see from those numbers that between 2,400 and 4,200 rpm, the engine probably produces between 200 and 220 lb-ft of torque.

What about at higher speeds? We know that the engine never produces more than 160 horsepower. Even if it still produced 160 horsepower at 5,000 rpm (which is unlikely), torque would have dropped to 168 lb-ft at that speed. If it produced 140 horsepower at 5,000 rpm, that would mean that its torque output was down to 147 lb-ft. In short, the Ford engine’s torque and power both start dropping off very rapidly after the 4,200-rpm horsepower peak — the V6 was designed for low-end grunt, not high-rpm power.

What about the Volkswagen engine? The 1.8T’s peak torque begins at 1,950 rpm. At that speed, it’s making only 64 hp (173 lb-ft x 1,950 rpm / 5,252). By 2,400 rpm (the Ford’s torque peak), the VW engine’s horsepower has risen to 79. At 4,200 rpm, the 1.8T has risen to 138 hp, still well behind the Ford. The VW’s power doesn’t start to exceed that of the Ford engine until after the Ford hits its peak power. When the VW hits its peak horsepower at 5,500 rpm, torque is still about 172 lb-ft — torque has tapered off, but only very slightly. That means the engine continues to make useful power even past its power peak; its redline is 6,500 rpm, which it doesn’t have much trouble reaching.

These torque and horsepower curves are estimates based on published power and torque figures, but they illustrate the difference between the engines. Note that even though the VW’s torque curve (light green) is far flatter than the Ford’s, the Ford’s is higher over much of the rev range.

What does this mean in practical terms? Even though the VW’s torque curve is very flat, it has significantly less torque than the Ford until well over 4,200 rpm, which means that the 1.8T also has less power at lower speeds. It ultimately produces more power than the Ford engine, but not until over 5,000 rpm.

Imagine that we installed these engines in two otherwise identical cars, with the same transmissions, same gearing, and identical weight. We would discover the following:

- In normal, street driving, the car with the Ford engine would almost always be quicker than the VW-powered car. That shouldn’t be surprising — the Ford’s greater torque gives it almost 30% more power than the VW engine at low rpm, even if the VW is stronger at higher speeds.

- In a drag race over a standing quarter mile or standing kilometer, the Ford-powered car would take an early lead and would stay ahead until both cars were well down the strip. The 1.8T car would begin to catch up as it hit higher engine speeds and it would eventually pull ahead. It would win by a narrow margin and its trap speed (its speed at the finish line) would be slightly higher than the Ford-powered car’s.

- In a road race or on a big NASCAR-style oval track, the VW-powered car would be ahead most of the time. As long as both cars were driven flat out, the VW engine’s greater horsepower would be more important than the Ford’s low-speed torque. The only place the Ford-powered car would have an advantage would be in slow corners, where its higher torque would again give it more power than the VW engine.

This assumes everything else is equal, which in the real world isn’t necessarily the case. For example, we could help the VW-engined car by changing its gear ratios so that the engine is always running at higher rpm. This would give it more power in low-speed driving, although it would also mean more engine noise, greater fuel consumption, and somewhat higher engine wear.

Subscribe to:

Posts (Atom)